Blogs

How to Install and Cut LED Strips Properly: A Step-by-Step Guide

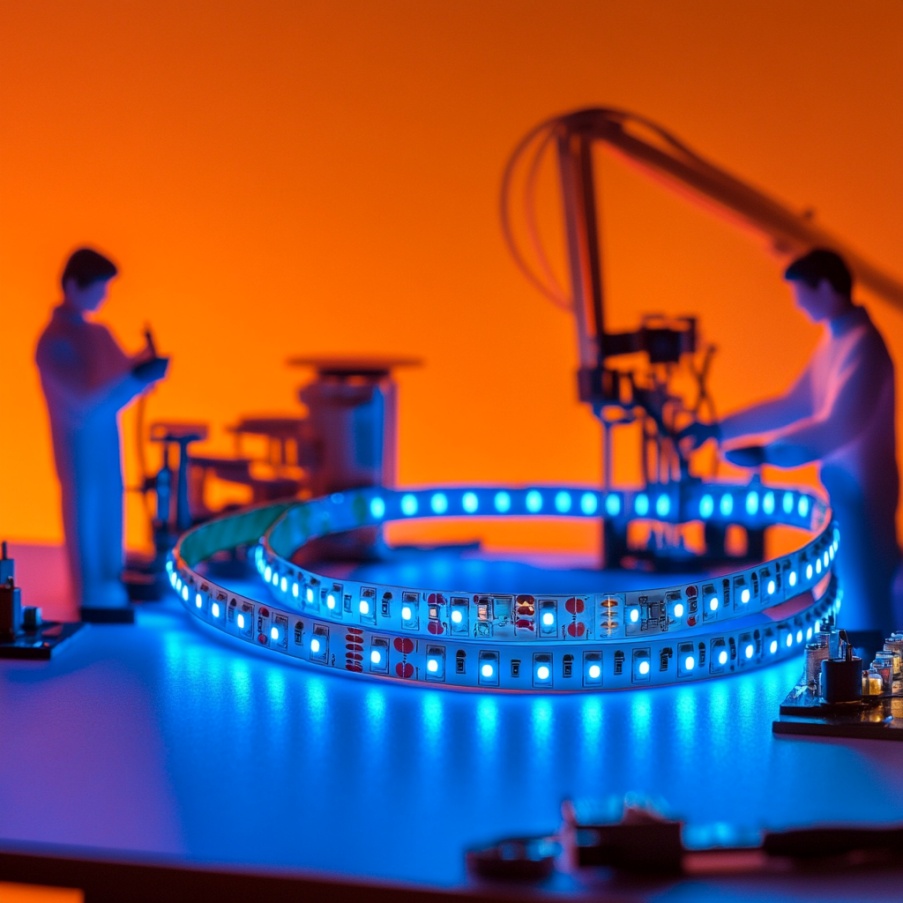

LED strips are a popular choice for both residential and commercial lighting due to their versatility, energy efficiency, and sleek design. Whether you're illuminating a kitchen, creating ambient lighting in a living room, or adding accents to a workspace, LED strips can provide a seamless, customizable lighting solution. However, for optimal results, proper installation and cutting techniques are essential to avoid damaging the strips or affecting their performance.

In this comprehensive guide, we’ll walk you through how to install and cut LED strips properly, ensuring your lighting project goes smoothly and the LEDs function at their best.

What You Need for Installation and Cutting LED Strips

Before you begin, gather the following tools and materials:

LED strip lights (ensure they are the correct voltage and type for your project)

Power supply (matched to the voltage of your LED strips)

Soldering iron (for connections, if necessary)

Wire cutters or scissors (for cutting the LED strip)

Measuring tape (for accurate measurements)

3M adhesive backing (if you want to use peel-and-stick installation)

Aluminum channels (optional, for better heat dissipation and a polished look)

Connectors (optional, for connecting strips without soldering)

Once you have everything ready, it’s time to start the installation.

Step 1: Plan Your Installation

Before diving into installation and cutting, planning is key to achieving a professional finish. Consider the following factors:

1.Measure the Area: Use a measuring tape to determine the length of the area where you’ll be installing the LED strips. Make sure to leave some space for any connectors or power supplies.

2.Choose the Right LED Strip: Ensure that you’re using the correct type of LED strip for your application. For example, high-density strips are better for ambient lighting while waterproof strips are ideal for outdoor use. Additionally, check the voltage rating (e.g., 12V or 24V) of the LED strips to match the power supply.

3.Check for Power Supply: Choose a power supply that matches the voltage and wattage requirements of your LED strips. Overloading a power supply can damage both the strip and the supply itself.

4.Pick the Right Accessories: If you need to cut the LED strips or make complex connections, consider using LED connectors for a hassle-free experience. For more permanent installations, soldering the connections might be necessary.

Step 2: Cutting LED Strips

LED strips can be easily cut to fit your space, but you need to follow specific steps to ensure they function correctly after cutting. Here's how to do it:

1.Locate the Cutting Marks:

Most LED strips have clearly marked cutting points, which are usually indicated by a scissors icon and a dashed line. These marks are spaced at regular intervals (typically every 3-5 cm). Cutting along these lines ensures that the circuit is properly interrupted without damaging the individual LEDs.

2.Use the Right Tools:

Use sharp scissors or a wire cutter to cut the LED strip. It’s essential to make a clean cut along the marked line. Cutting at any other point can damage the internal circuitry, leading to malfunctioning LEDs.

3.Check the Cut:

After cutting, examine the strip to make sure that the copper pads on the cut end are intact. These pads are where you'll connect wires or connectors. If the copper is damaged, it might affect the strip’s functionality.Optional Soldering:

If you plan to connect the cut end of the LED strip to a power supply or another strip, you can either use soldering or connectors. Soldering is a more permanent and reliable solution, while connectors are easier and faster but might not be as secure.

a. To solder, strip the insulation from the wire and solder it to the copper pads on the cut end of the LED strip. Make sure to use a low-wattage soldering iron to avoid damaging the strip.

b. If you prefer to use connectors, simply insert the cut end into the connector, ensuring a secure and tight fit.

Step 3: Installing LED Strips

Now that you’ve cut the LED strips to the desired length, it’s time to install them. Here’s how to install LED strips properly for optimal performance:

1. Prepare the Surface

Make sure the surface where you plan to install the LED strip is clean, dry, and free from dust or grease. Use a clean cloth to wipe the area, as dirt can interfere with the adhesive backing on the LED strip.

2. Peel and Stick Installation (For Adhesive Backing)

Most LED strips come with an adhesive backing for easy installation. If yours does, here’s how to proceed:

Peel off the protective paper from the adhesive side of the strip.

Press the strip firmly onto the surface, making sure it is straight and evenly aligned.

For long installations, press down gradually, ensuring the adhesive sticks evenly.

3. Using Aluminum Channels or Mounting Clips

If you’re aiming for a more polished and secure installation, consider using aluminum channels. These channels not only help to improve heat dissipation but also provide a clean, professional finish.

Place the LED strip inside the channel and secure it with the adhesive backing.

Mount the channel to your surface using the included clips or screws.

4. Power Up the LED Strip

Once the strip is securely installed, connect it to the power supply. Make sure to match the input voltage on the power supply with the voltage rating of the LED strip.

For 12V strips, use a 12V power supply.

For 24V strips, use a 24V power supply.

5. Test the Installation

Before securing everything in place, plug in the power supply and test the LED strip. Ensure that it lights up evenly and that there are no issues with flickering or dim sections.

Step 4: Troubleshooting and Maintenance

After installation, you may encounter a few issues. Here’s how to troubleshoot:

If the LEDs don’t light up, check the connections and ensure that the power supply is properly connected. Also, verify that the power supply is suitable for the voltage and wattage of your LED strip.

For flickering LEDs, make sure you’re using a suitable dimmer or a PWM controller if necessary.

If parts of the LED strip are not working, check if the copper pads on the cut edge are intact and properly connected. You may need to re-solder or reconnect the strips.

Conclusion: The Right Way to Install and Cut LED Strips

LED strips are a great way to add versatile, energy-efficient lighting to your space. By following the proper installation and cutting procedures, you can ensure your LED strips perform at their best. Here’s a quick recap of the key steps:

Measure the area and choose the right type of LED strip for your needs.

Cut along the marked cutting lines using sharp tools, and make sure to properly connect any cut ends.

Install by cleaning the surface, applying adhesive backing, or using aluminum channels for a more professional finish.

Test your installation and troubleshoot any issues.

With these tips, you’ll be able to create a seamless and functional LED strip lighting setup that enhances the ambiance and efficiency of any room. Happy lighting!

RELATED NEWS

- Are Daylight LEDs Too Bright for a Living Room?Are Daylight LEDs Too Bright for 2025-04-17

- How Do I Choose the Right LED Strip for Under-Cabinet Lighting? 2025-04-17

- Why Do My LED Lights Flicker Even When Using a Dimmer? 2025-04-10

- How Do I Know If My LED Strip Is Getting Enough Power? 2025-04-10

- How Much Energy Can You Save by Switching to LED Lights? 2025-04-03

CATEGORIES

LATEST NEWS

CONTACT US

Contact:

Phone:

E-mail: jessica@ledfocus.cn

Whatsapp:

Add: 983-984, Building B, Qinghu Industrial Park, Qingxiang Road, Qinghu Community, Longhua Street, Longhua District, Shenzhen, China